Hi Folks,

I recall I was sitting in a lobby, surrounded by plush carpets and sofas. There was a gentle, quiet trickle from a nearby fountain and a pleasant tropical fragrance in the air. It was a nice change from the rough industrial facilities I oft visited as part of my energy assessment work.

I was there for a meeting with a company operating high-end serviced apartments, to review designs for a new building. As I walked with one of the facilities management team towards our meeting room, I asked some general questions about the building. He whispered quietly that the guests were often complaining the rooms weren’t cold enough (we were in the tropics). The primary reason, according to my host, was that the air-conditioning system was frequently leaking refrigerant…

We moved on to other topics and had our meeting, but his comment stuck with me. As some of you may recall it took a few years working in energy efficiency to become really aware of the problem of refrigerants. Here was another example.

The Charge

As a quick recap for those outside the industry. One large source of climate damaging emissions from refrigerants comes from when they leak to atmosphere during equipment operation.

All refrigerant equipment leaks to some degree. From tiny amounts (e.g. home refrigerators) to those that leak 20-30% p/year, often the systems which are ‘assembled’ in the field. Such as supermarket systems with long refrigerant-containing pipe runs going to the various chilled cabinets, where you buy your cheese.

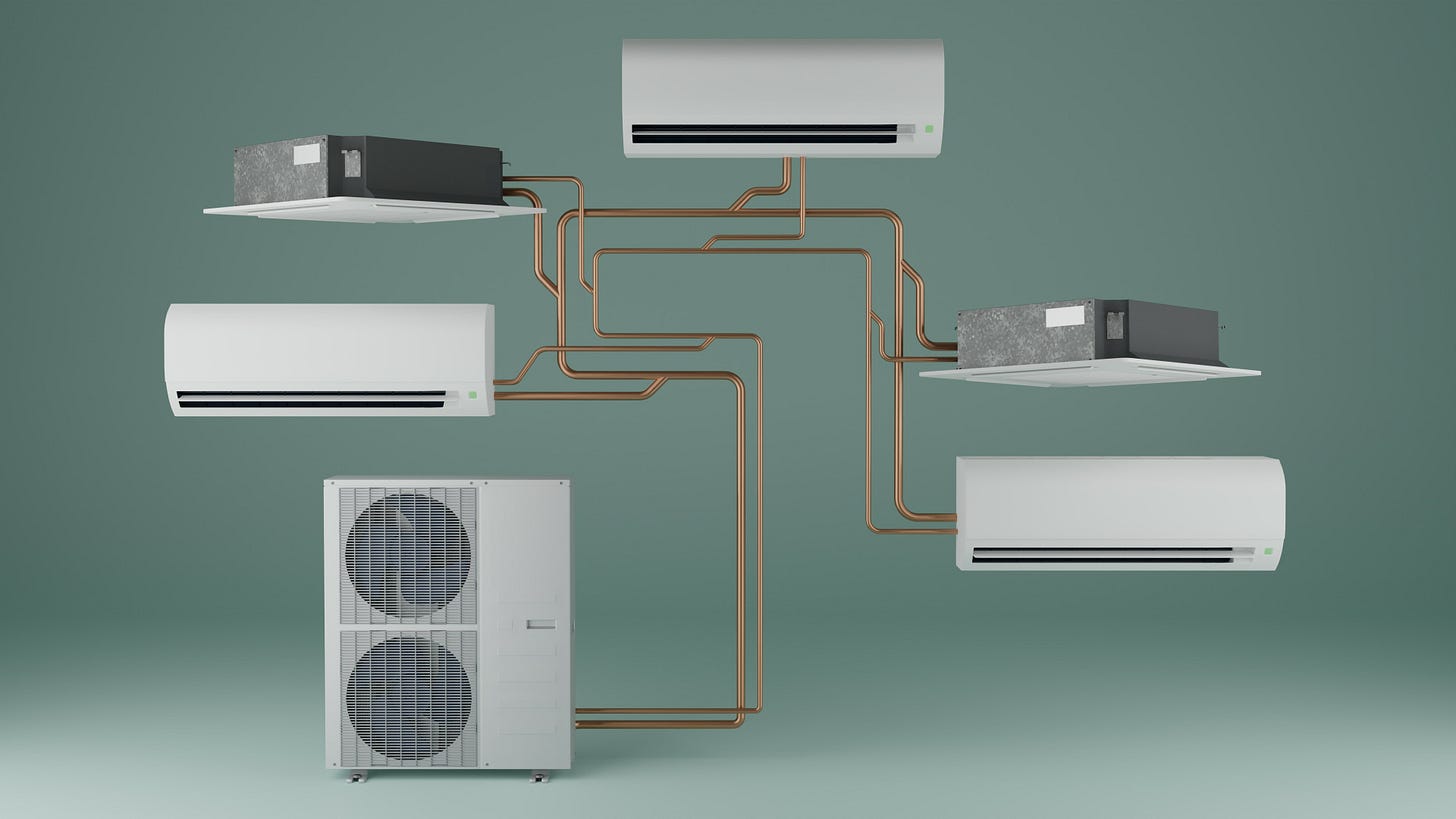

Another system prone to leaks are variable refrigerant flow (known as VRV or VRF) systems. It was the type used in the serviced apartments I visited at the top of this article. Without diving too deep into how they work, like the supermarket they have many long pipes, assembled onsite (sometimes a bit too hastily) during the building construction process. The multitude of joints connecting these long pipe runs are a common source of refrigerant leaks.

VRV systems can be very energy efficient when installed well. With the right type of piping and well-constructed joints they are very good systems. As in a lot of cases it comes down to the quality of the installers and materials and tooling used.

However, the main topic I wanted to address here is the ‘charge’ size.

In the industry ‘charge’ refers to the amount of refrigerant installed within the whole system; be it a fridge, car or building air-conditioner. Longer piping requires more refrigerant and a larger charge size. In short, more banked emissions stored up in the system.

This is where the idea of hybrid systems can make sense. Where instead of having piping serving refrigerant all the way to the endpoints (i.e. apartments) you replace it with alternative fluids which don’t pose an emissions risk. In the case of hybrid VRVs, this could use a heat-exchanger and water to the conditioned spaces. This also reduces the risk of refrigerant gas leaking in human populated spaces.

For another example, I recall working with a water-cooled condenser in a supermarket. It was a bit fiddly to get the pumps working well, and at the time I questioned the bit of extra energy used to circulate the water instead of a traditional refrigerant circuit.

However now, looking at it through an emissions lens I can see the rationale. There are overall life-cycle emission benefits from having a smaller charge, and less opportunity for leaks. Like hybrid cars, they are not perfect, but they can offer an improvement if an owner has decided to go the synthetic refrigerant route.

The message about charge sizes was further highlighted in a recent webinar featuring Prof. Michael Kauffeld, who has been working with refrigerants for many years. He used the example of a deodorant spray, which in the past contained up to 180 grams of propellant. It is now produced using just 25 grams to deliver the same performance. The lesson; with R&D and regulatory encouragement, manufacturers can find ways to do more with less.

Take also the recent work by Fraunhofer ISE and the LC150 (low-charge 150) program. The effort to squeeze as much performance as possible out of just 150 grams of R290 in a heat pump application (smaller than what was in the original can of deodorant). In short, they have been able to generate over 12kW of heating, which is quite phenomenal, and what you would normally get from a much bigger system.

Reducing the need for mechanical cooling and heating in the first place is key. Demand reduction, insulation, heat recovery and integrative design thinking such as that championed by Amory Lovins. However, next up should be trying to keep the refrigerant charge sizes as low as possible, while using natural refrigerants.

The takeaway here. Refrigerant emissions are a function of the type of refrigerant and the amount leaking. Using less pipework, less joints, and less refrigerant will all help.

Where the F Gas Hides

Each week I provide an example of where f-gases are utilised, or used to produce something. They are present in more things than most people realise…

While there may be valid (but shrinking) arguments for the continued use of fluroinated refrigerants in some essential use cases. There are also some applications of f-gases which are just - silly.

Silly Crazy Party String

Some may recall that one of the more public efforts for ozone action was removing CFCs from aerosol products, deodorants and hair sprays etc. This was generally successful, and some manufacturers developed other propellant solutions. However, like the refrigeration industry, some stayed with fluorinated (f-gases) utilising hydrofluorocarbons HFC-134a and HFC-152a given their stability and low-flammability.

The problem is that for many applications, like silly string, much of the spray can content is the propellent itself. The f-gas in compressed liquid form which gets released straight to atmosphere along with the string.

Silly string is particularly daft. Not only are you spraying single use plastic resin and foaming agents (not great) but also releasing f-gas at the same time. There are string manufacturers using climate damaging HFCs and now we are seeing increasing use of HFO f-gases in their place. These have a ‘low-GWP’ label but there is concern over their other environmental impacts (i.e. classed as PFAS).

While in the EU there are steps being taken to restrict their use, it seems that for the time being in some countries it is still acceptable to allow your kids to spray fluorinated chemicals over each other in the name of a good time. Go figure.

Right, that’s all for this week and till next time,

Adrian

Fixed stuff here for newcomers

There is lots of news every week from the cooling industry and plenty of newsletters that cover it well. The intention is to keep this newsletter focused on the most prominent f-gases (fluorinated greenhouse gases), the most common of which are refrigerants and importantly their environmental impact. That’s the lane I’ve chosen - I’ll do my best to stick to it.

The What

Below is the seven (formal) greenhouse gases that countries and companies should track, report and hopefully reduce.

Carbon Dioxide (CO2)

Methane (CH4)

Nitrous Oxide (N2O)

Hydrofluorocarbons (HFCs)

Perfluorocarbons (PFCs)

Sulphur Hexafluoride (SF6)

Nitrogen trifluoride (NF3)

There is also the still circulating, ozone damaging chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs), and the ‘new-generation’ hydrofluoroolefins (HFOs).

Hopefully you can spot the pattern.

The Why

Emissions from f-gases and refrigerants have been the fastest growing greenhouse gases over the past decade (more than CO2 and methane - check out IPCC WG3 summary for policy makers). They are also classed as super pollutants given their outsized global warming and other environmental impacts.

You can find my basic primer here and a plenty more detail in the whitepaper here

Some useful permalinks

The scale of the climate challenge can often feel daunting. This piece helps me take a step back and understand where we need to focus first - recommend a read.

There are plenty of technology solutions available to address the cooling and refrigerant challenge. You can find many of them here

Beware when the same entities who have contributed to the current f-gas problem propose you new solutions… This is a good place to get up to speed.