Hey folks,

Up to this point you might have got the impression (correctly) that many of my posts have been focused on ‘The Problem’. The environmental and climate issues associated with fluorinated refrigerants, of which there are plenty.

I figured, that before one starts talking about solutions, one needs to communicate the depth and extent of those first.

That isn’t to say that I’ve covered all the aspects or nuances. But perhaps there is enough of a grounding to start shifting focus a little bit.

If you’ve recently joined however, and don’t have the time to review everything, then I’d suggest starting with these:

and

The last edition also attempts to put the scale of the problem into context. I’d recommend it if you can find a moment.

So with a bit of grounding in place, let’s start to look at what’s needed to make a genuine difference. I’m going to start high-level today, and we’ll drop deeper into the various sub-topics in upcoming editions.

Standing firm

Some folks will be familiar with the three-legged stool analogy. The one where a given principle requires three (roughly) equal ‘legs’ to hold up. Take one leg away, and the idea no longer stands. The analogy isn’t perfect, but given its familiarity to people, I’ll use it to introduce some ideas.

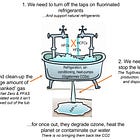

You might recall some time back, I described what we need to do to address the three core problem areas

Turn off the taps on fluorinated refrigerants and use alternatives

Stop the leaks on existing systems

Clean-up the mess of existing refrigerants

Or more simply: Switch-up, Tighten-up & Mop-up

To start with. If we’re not turning off the taps on fluorinated refrigerants, then we’re making the other two other tasks so much harder.

The obvious example being; if the bath is overflowing in your house, the first thing you do is turn off the taps before you start cleaning the mess.

Switch-up

Some might ask, what is the point at which fluorinated refrigerants overflow. There is no hard ‘edge’ on how much we can produce, contain in equipment, or even put into the atmosphere. Except there is now sufficient knowledge to understand we’ve already breached the planetary boundaries for climate, ozone and chemicals. We’re overflowing already.

It is time to turn off the taps, and switch-up to better alternatives. We’re going to need cooling, electrified heat and refrigeration in growing numbers over the coming decades. We’ll certainly still need refrigerants. Fortunately, we have solutions and I’ll be exploring those in coming editions.

Tighten-up

For equipment that is already in the field, containment and leak prevention (for all types of refrigerant) is absolutely paramount. Leaks are one of the primary ways that refrigerants enter the atmosphere. At the same time, leaks lead to more energy use and replacement and maintenance costs. As they are invisible however, they are often only fixed once a significant amount has already leaked.

If we’re not tackling leaks, we’re not tackling one of the root causes of the problem. Fortunately, there is also plenty we can do to address leaks. To tighten-up our refrigerant-containing equipment and systems, big or small.

Mop-up

This is arguably one of the hardest legs to deal with. If we do a good job turning off the taps, and tightening-up the systems mitigating leaks, it still leaves us with a huge amount of refrigerant waste to deal with.

And it is always a waste problem. It is only a climate problem or ozone problem if released.

And as we’re already overflowing there is no way we can let it out. So then what? We could potentially re-use some of it to keep existing systems running, but that will only get us so far.

Making sure refrigerant isn’t released when equipment is disposed of, is in itself a huge challenge.

The final destination for fluorinated refrigerants is set however. Not to say that destruction is the only option on the table, but it is one of them. Some non-fluorinated refrigerants will also need to be closely handled in a zero-emissions world.

There is lots of ground to cover, and I’ll be digging into these further in the upcoming editions. Stay tuned.

#wherethefgashides

In this section I provide an example of where f-gases are utilised, or used to produce something. They are present in more things than most people realise…

You may recall I’d written previously about some of the common places you’re likely to find refrigerants travelling through an airport. From the refrigerated vending machines, through to the air-conditioned gangways.

Another one to include, is found in the hold of the aircraft. Refrigerated cargo containers.

ULDs

While a lot of refrigerated goods go buy sea, there are some that go by air. Often those that are time sensitive, such as vaccines.

If you’ve travelled by plane, you would have likely seen the silver containers being loaded into the aircraft hold (referred to as ULDs or unit load devices). Most of these are not temperature controlled, but there are some units which include cooling for temperature sensitive goods.

There are generally two types of temperature controlled ULDs – active and passive. Passive being simpler and often use dry ice (a solid form of carbon dioxide) for the cooling without the need for any electrical input. Active types are supported by batteries and some utilise a vapour-compression system using refrigerants.

For most other types of refrigeration systems out there, it is generally easy enough to find out what sort of refrigerant is being used. In the case of the temperature controlled ULDs it was a bit harder and I couldn’t find any supplier disclosing the refrigerant used.

It led me to call on a trusted source within the transport refrigeration industry who confirmed that the refrigerant R134a (GWP 1530) is often used, given its wide availability and familiarity along the cold chain. Yet another place where the f-gas hides.

Right, that’s all for this week and ‘till next time.

Adrian

p.s. the title track from last edition – Drawing down the moon – was from The Tea Party and the album Edges of Twilight. Quite the act to see live.

Small Ask

While I enjoy writing this Newsletter I also need to keep the lights on. If you know any companies or organisations that need support with managing and reducing emissions from refrigerants, feel free to reach out to me. You can reply on the email or check out Veridien RM for more information on where I can help. Merci :)

Fixed stuff here for newcomers

There is lots of news every week from the cooling industry and plenty of newsletters that cover it well. The intention is to keep this newsletter focused on the most prominent f-gases (fluorinated greenhouse gases), the most common of which are refrigerants and importantly their environmental impact. That’s the lane I’ve chosen - I’ll do my best to stick to it.

The What

Below are the seven formal greenhouse gases that countries and companies should track, report and hopefully reduce.

Carbon Dioxide (CO2)

Methane (CH4)

Nitrous Oxide (N2O)

Hydrofluorocarbons (HFCs)

Perfluorocarbons (PFCs)

Sulphur Hexafluoride (SF6)

Nitrogen trifluoride (NF3)

Plus the still circulating, ozone damaging chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs), and the ‘new-generation’ hydrofluoroolefins (HFOs).

Hopefully you can spot the pattern.

The Why

Emissions from f-gases and refrigerants have been the fastest growing greenhouse gases over the past decade (more than CO2 and methane - check out IPCC WG3 summary for policy makers). They are also classed as super pollutants given their outsized global warming and other environmental impacts.

You can find my basic primer here and a plenty more detail in the whitepaper here

Some useful permalinks

The scale of the climate challenge can often feel daunting. This piece helps me take a step back and understand where we need to focus first - recommend a read.

There are plenty of technology solutions available to address the cooling and refrigerant challenge. You can find many of them here

Beware when the same entities who have contributed to the current f-gas problem propose you new solutions… This is a good place to get up to speed.